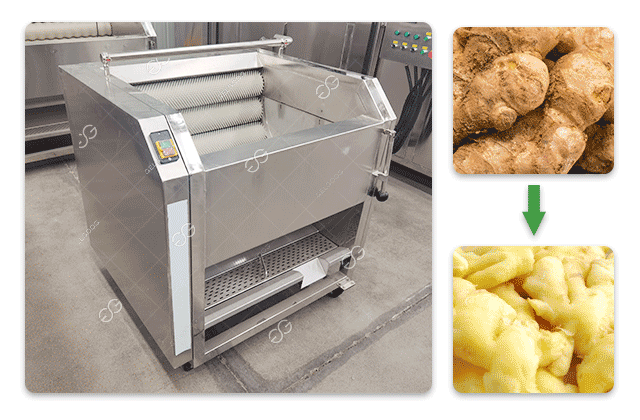

Automated Ginger Cleaning and Peeling Machine Price

Output: 400kg-2000kg/h

Voltage: 380V

Material: Stainless steel

Whether it can be customized: Support customized

Usage: Suitable for cleaning and peeling ginger, radish, carrot, sweet potato, and other root fruits and vegetables

Description

The ginger washing and peeling machine is a device used for cleaning and peeling ginger and other root vegetables. Often used in conjunction with brush cleaning and peeling machines. This equipment can automatically process ginger, with output from 400kg/h to 2000kg/h. You can choose according to your actual needs. We support the customization of different outputs and equipment size specifications.

This equipment is suitable for batch processing of ginger. Automated processing equipment can improve production efficiency and reduce labor costs. The automated ginger washing and peeling machine usually uses the working principle of one or more sets of rotating brushes to gently remove dirt and skin on the surface of the ginger through physical friction. It also cooperates with a high-pressure spray system to quickly rinse with clean water to ensure that the ginger is clean and free of residue.

Since ginger is relatively fragile, controlling the hardness and speed of the brush can ensure efficient peeling without damaging the ginger.

Features of Ginger Cleaning and Peeling Machine

1. Automatic cleaning and peeling machines are usually equipped with automatic feeding, cleaning, peeling, and discharging systems, which are easy to operate.

2. According to the size of the ginger and peeling requirements, parameters such as brush pressure and spray water volume of the equipment can be adjusted to achieve the best cleaning effect.

3. The automated ginger washing and peeling machine is made of food-grade stainless steel to ensure hygienic safety during ginger processing and facilitate later processing and consumption.

4. Automatic or semi-automatic processing methods are optional, and can be used with the production line to achieve fully automated ginger cleaning and peeling, and later processing of deep-processed products.

5. Low maintenance costs: Durable materials and structural design reduce the frequency and cost of maintenance in long-term operation and extend the service life of the equipment.

Advantages of Ginger Cleanng and Peeling Machine

1. The machine is an efficient cleaning and peeling machine with good results: through the high-speed rotating brush, the ginger is fully rolled and rubbed in the machine, effectively removing surface soil and skin. At the same time, it is rinsed with a spray system to ensure that the ginger is quickly and easily peeled. Clean thoroughly;

2. Reduce damage: The professionally designed brush material and force control can minimize the damage to the ginger while peeling it, maintain the integrity of the ginger, and reduce waste;

3. High output: The ginger cleaning machine has a high processing capacity and can process thousands of kilograms of ginger per hour. It is suitable for large-scale production needs, is easy to maintain, and key components are easy to replace;

4. Wide applicability: In addition to ginger, the ginger peeling machine can also be used for cleaning and peeling other root vegetables such as potatoes, carrots, etc., which enhances the versatility and economic benefits of the equipment.

Parameters

| Model | Power | Dimension | Weight | Capacity | Roller length |

| GG-SX800 | 1.1kw/380v | 1600*850*800mm | 220kg | 400kg/h | 800 mm |

| GG-SX1000 | 1.5kw/380v | 1800*850*800mm | 260kg | 600kg/h | 1000 mm |

| GG-SX1200 | 1.5kw/380v | 2000*850*800mm | 280kg | 800kg/h | 1200 mm |

| GG-SX1500 | 2.2kw/380v | 2300*850*800mm | 320kg | 1000kg/h | 1500 mm |

| GG-SX2000 | 3kw/380v | 2800*850*800mm | 420kg | 1500kg/h | 2000 mm |

| GG-SX2600 | 4.75kw/380v | 3300*850*1450mm | 600kg | 2000kg/h | 2600 mm |