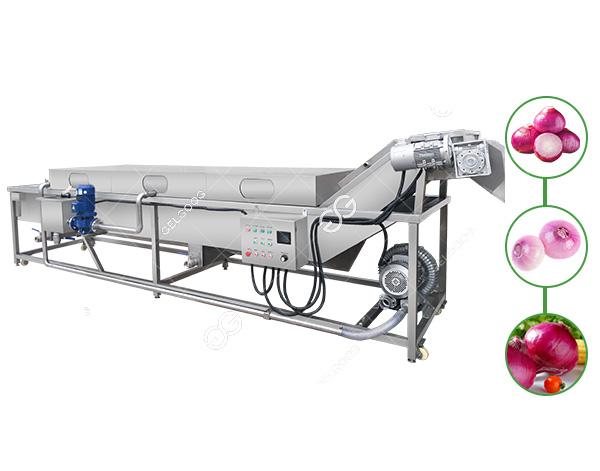

Air Bubble Onion Cleaning Machine Multifunctional for Sale

Voltage: 380V

Material: Stainless steel

Whether it can be customized: Support customization

Usage: Used for cleaning onions

Description

The onion cleaning machine is a mechanized equipment carefully built for the pretreatment process of cleaning onions.

Onions are also called onions. As one of the most commonly eaten vegetables, onions need to be peeled and cleaned before being processed. They are widely used in vegetable processing plants, snack processing plants, condiment processing plants, and other food processing plants.

The machine has a built-in bubble generation system that releases dense micro-bubbles. When these bubbles rise in the water, they gently and deeply massage the surface of the onion to clean it, effectively peeling off soil and impurities, while carefully protecting the appearance of the onion and reducing physical damage.

After the initial bubble cleaning, a second fine spray unit is added to use fresh water to wash the onions again to ensure a flawless final cleaning effect.

Advantages of Onion Cleaning Machine

1. Precise high-pressure water flow system: Equipped with precision-controlled high-pressure sprinkler heads, the water flow intensity is adjusted according to the characteristics of onions and penetrates deep into gaps to completely remove stubborn stains and potential pesticide residues, ensuring the purity of every onion.

2. Intelligent conveyor belt drive: The multi-functional onion cleaning machine adopts an automatic conveyor belt made of food-grade stainless steel, which not only speeds up onion processing and enables continuous automated operations, but also greatly reduces the labor burden and improves production fluency.

3. Humanized intelligent control interface: This air bubble onion cleaning machine integrates an intuitive and easy-to-use control system. Users can flexibly adjust cleaning time, water flow pressure, and other parameters according to the different sizes and cleaning difficulty of onions to achieve personalized cleaning plans.

4. Environmentally friendly and water-saving design: The innovative circulating water treatment combined with the automatic water changing system effectively maintains the cleanliness of the cleaning water, reduces the waste of water resources, and demonstrates the concept of green production.

Why Choose Us?

1. Support customization: Based on the needs of each customer, we will ensure that the customized onion washing machine perfectly fits your business needs, optimizes cleaning efficiency, and helps enterprises upgrade their personalized production processes.

2. Professional team: Gelgoog has a technical and service team that brings together industry elites, including pre-sales consultation, R&D engineers, on-site installation, and after-sales personnel. Team members not only have deep industry knowledge but also rich practical experience.

3. Provide a full set of solutions: We tailor automatic onion cleaning machines or onion cleaning cutting production line solutions for you, including comprehensive solutions including equipment selection, process design, and workshop layout planning, to help you build an efficient and automated production system to enhance overall competitiveness.

4. Numerous customer cases: With many years of experience in the field of food processing equipment, we have successfully provided satisfactory solutions to 6,000+ customers around the world.

Parameters

| Model | Mesh belt width | Transmission power | Pump power | Air pump power | Dimensions(MM) |

| GG-XQ2500A | 800 | 0.75 | 0.75 | 2.2 | 2725×1504×1329 |

| GG-XQ3000A | 800 | 0.75 | 0.75 | 2.2 | 3225×1504×1329 |

| GG-XQ3500A | 800 | 0.75 | 0.75 | 2.2 | 3725×1504×1329 |

| GG-XQ4000A | 800 | 0.75 | 0.75 | 2.2 | 4225×1504×1329 |

| GG-XQ5000A | 800 | 1.5 | 1.5 | 4 | 5225×1504×1329 |

| GG-XQ6000A | 800 | 1.5 | 1.5 | 4 | 6225×1504×1329 |